Raw materials used in automobile industry

Background

Glass is a flexible material with a huge selection of applications, including windshields. Glass features a lengthy record and was first made more than 7, 000 years back in Egypt, since 3, 000 B.C. Glass is found in an all natural condition as a by-product of volcanic task. These days, glass is manufactured from a number of ceramic materials (primary elements are oxides). The main product categories tend to be level or float cup, container cup, cut-glass, fiberglass, optical cup, and specialty glass. Automotive windshields belong to the level cup group.

There are many than 80 companies worldwide that produce automotive glass, including windshields. Major manufacturers in the United States include PPG, Guardian Industries Corp., and Libby-Owens Ford. In accordance with the division of Commerce, 25 % of flat glass production is eaten because of the automotive business (including house windows) at a total value of more or less $483 million. In Japan, 30 percent of flat glass visits the automotive business, appreciated at around $190 billion in 1989. Major Japanese level glass makers consist of Asahi Glass Co., Central Glass Co., and Nippon Sheet Glass Co. Little development is expected when it comes to flat cup business overall in both nations. Germany has actually an even more positive perspective, with high development rates anticipated from the automotive industry.

Glass windshields very first showed up around 1905 with the creation of security glass—glass tempered (tempering is a heat application treatment) making it especially tough and resistant to shattering. This kind of windshield had been popular well in to the center associated with the century, however it ended up being eventually changed by windshields made from laminated glass—a multilayer product composed of a plastic layer in the middle of two sheets of cup. In lots of nations, including the U.S., automobile windshields are required legally to-be made of laminated glass. Laminated cup can flex slightly under influence and it is less likely to shatter than usual security cup. This quality decreases the risk of problems for the automobile's individuals.

Raw Materials

Glass comprises many oxides that fuse and react collectively upon heating to make a cup. Included in these are silica (SiO 2 ), salt oxide (Na 2 O), and calcium oxide (CaO). Raw materials where these products tend to be derived are sand, soda ash (Na 2 CO 3 ), and limestone (CaCO 3 ). Soda ash acts as a flux; put simply, it lowers the melting point associated with group structure. Lime is added to the batch to increase the stiffness and chemical durability for the cup. Glass employed for windshields in addition frequently includes other oxides: potassium oxide (K 2 O based on potash), magnesium oxide (MgO), and aluminum oxide (AI 2 O 3 based on feldspar).

The Production

Process

- 1 The garbage are carefully considered inside proper quantities and mixed and a small amount of liquid to stop segregation of the components. Cullet (broken waste glass) is also utilized as a raw product.

- 2 when the batch is manufactured, it's given to a sizable container for melting with the float

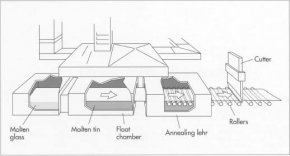

The cup for automible windshields is made utilizing the float glass process. Within strategy, the raw product is heated to a molten condition and fed onto a bath of molten tin. The glass actually floats along with the fin; due to the fact fin is completely level, the cup additionally becomes flat. From the float chamber, the glass passes on rollers through an oven (the "annealing lehr"). After leaving the lehr and air conditioning to room-temperature, the cup is slashed to your appropriate form and tempered.

cup procedure. First, the group is heated to a molten state, and then its fed into a tank labeled as the float chamber, which holds a bath of molten tin. The float chamber is extremely large—from about 13 foot to 26.25 foot (4 to 8 yards broad and up to practically 197 legs (60 meters) very long; at its entry, the heat for the tin is all about 1, 835 degrees Fahrenheit (1, 000 levels Celsius), while on exit the tin's temperature is slightly cooler—1, 115 degrees Fahrenheit (600 levels Celsius). Inside float chamber, the glass doesn't submerge into the tin but floats on top of it, moving through container like on a conveyor gear. The perfectly flat surface for the tin causes the molten glass also to be flat, even though the large temperatures wash the glass of impurities. The reduced heat at exit regarding the chamber allows the glass to harden enough to move into next chamber, a furnace. - 3 After the glass exits from the float chamber, rollers choose it and give it into a particular furnace labeled as a lehr. (If any solar power coatings are desired, these are typically used prior to the glass gets in the lehr.) Inside furnace, the glass is cooled gradually to about 395 degrees Fahrenheit (200 degrees Celsius); following the cup exits the lehr, it cools to room-temperature. It is now very difficult and powerful and ready to be cut.