RFID in automotive industry

From Ford to Fahrvergnügen, RFID Expands the chance to Streamline manufacturing and Lower production expenses

From Ford to Fahrvergnügen, RFID Expands the chance to Streamline manufacturing and Lower production expenses

In 1885, Karl Benz built the initial car run on an internal burning gasoline motor and began the production of cars in 1888. In 1908, the Model T had been introduced because of the Ford Motor business, accompanied by the introduction of the assembly-line approach to mass manufacturing. Henry Ford’s dedication to streamlining manufacturing and lowering prices goes on when you look at the automotive business these days, which has even more difficulties and complexities than previously.

With elements supplied by more than 4, 000 suppliers and complex procedures like subassembly procurement and pre-delivery preparation, car producers tend to be challenged with maintaining a competitive side. Manufacturers continually want to get a hold of brand new how to enhance material circulation, optimize preparation and improve the transport process. Today, RFID is playing a vital role in handling these difficulties.

Using this week’s system concentrating on the transport market and having already been a Volkswagen owner for quite some time, I have an individual interest in covering Volkswagen’s use of RFID. Along with their commitment to production high quality while the innovative means they differentiate their particular brand, I’m never amazed by Europe's leading car manufacturer’s usage of RFID to operate a vehicle improvements in their supply chain and manufacturing procedures.

To boost its material logistics operations and apply a built-in, paperless production and logistics string, Volkswagen features partnered with IBM. Relating to an IBM statement, VW is driving in order to become the first car producer to create day-to-day utilization of RFID with its offer string and production procedures.

Shows of VW’s using RFID consist of:

- Components companies tend to be using RFID tags to delivery pots holding car parts destined for Volkswagen

- Information through the tagged bins is automatically collected by RFID Readers at crucial places through the supply sequence including supplier shipping places, various transportation things, parts getting areas at Volkswagen, during storage space, and on the assembly-line

- The exact same RFID system is employed to ensure all bare containers are gone back to Volkswagen’s companies

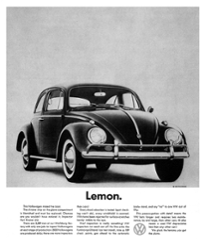

Given the dimensions and complexities of the automobile offer string and manufacturing procedure, businesses like Volkswagen tend to be implementing RFID to automate key areas of their operations. Do you really anticipate more automakers to implement similar applications to contend with the lemons coming off of production line? Let us know your thoughts.