Industrial Vibration Motor

7mm encapsulated vibration motor

7mm encapsulated vibration motor

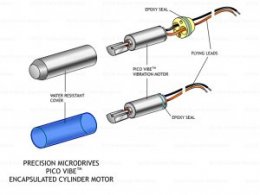

Encapsulated vibration motors are designed to be overmolded with low-temperature / pressure plastics to make them completely watertight, or seal all of them for use in harsh (example. corrosive) environments. They basically include a eccentric rotating mass vibration engine, housed in either a plastic or steel casing.

Typical programs of these sealed vibrating engines consist of:

325-100 25mm Encased Vibration Motor- Haptic feedback & vibration alerting for consumer products and commercial handheld equipment, specially if it's going to be used in a harsh environment

- Adult toys

- Healthcare equipment, especially the application has to be area cleansed or sterilised

Enclosed dildo engines were created like encapsulated vibration motors (with no exterior moving components), but also consist of screw holes regarding front most case dish. As a result their health are made of metal, unlike the unique red plastic you see on several of our encapsulated ERMs.

This makes it particularly convenient to attach all of them on rigid areas such as bulkheads and ruggedised / manufacturing control panels or dashboards.

Definitely, they are also perfect for programs where standard eccentric rotating size (ERM) vibration motors tend to be improper - as an example in conditions where there are particles or dirt.

Typical applications for enclosed vibration motors include:

- Vibration alerting, specifically for manufacturing control panels,

- Sorting devices,

- Blending Powders and emulsifying liquids,

- Aiding the movement of material down chutes, hoppers or through a funnels,

- Various other applications which need a vibration motor with protected going components.

Encapsulated Vibrating engine Design

Encapsulated Vibrating engine Design

All our encapsulated vibration engines are derived from a coreless design. The motors are covered with either metal or synthetic instances, and a ring of epoxy glue is used to secure these on engine body and offer the seal. In certain styles, e.g. the 306-108, the motor's traveling leads are after that more sealed to cut back ingression of product or fluids through the back of this engine.

Encapsulated (Sealed) Vibration MotorOvermolding & Sealing Vibration Motors

It's much simpler to completely secure encapsulated vibration engines than many other types of vibration motors, because of the decreased external moving components. Other forms, like enclosed vibration engines or money vibrator engines are apt to have holes for electric link or fasteners, helping to make them unsuitable for overmolding.

Water resistant casing and epoxy sealed traveling leads enables the usage of overmolding or over-casting for low-temperature and low pressure presses. As an alternative, there are a selection of hot-melt glues which can be used with a glue gun to secure the motor. Resins as well as other epoxy units may also be safely used more seal the engines. Besides making these encapsulated motors waterproof, these adhesives can help attach and keep the engines positioned.

Mounting Covered Vibration Motors

Mounting Covered Vibration Motors

If you don't installed through overmolding procedure, the alternative method for installing is to connect these encapsulated vibration motors toward application via a collet or similarly sized circular receptacle and secure either with a clamping screw or glue. For close tolerance steel enclosures rubberised Cyano Acrylate can be used efficiently, such as Loctite 480.

At a-pinch, although we might not endorse this for anything beyond an instant prototype, you may want to secure encapsulated vibration motors with a large dab of epoxy. You might like to rough the surface of the motor cover before you try this, to enhance the adhesion.

Encapsulated Vibration Engine Customisations

Our leaded encapsulation engines come as standard with 45mm flying leads (AWG 32, UL1571, PVC insulation). But for all clients we make variations of the base components which are identical in electrical and gratification specs, but which have different prospects, or a variety of connectors attached.

Common lead customisations include:

- Twisted prospects (in other words. intertwining them into a helix form),

- Alternate lead and strip lengths,

- Connections (example. AVX, Kyocera, Molex, Tyco).

Minimum purchase amounts make an application for these customisations, to go over your requirements thoroughly please cannot think twice to contact us using this link or the form at the bottom of the web page.

Wearable Haptic Feedback?

The major attraction for those sealed vibrator engines would be that they lack any additional going components. This not just allows the engines is overmolded into a design, but they may effortlessly be sewn into materials, including garments or vests.

One considerable issue of integrating haptic solutions into clothing is the fact that garments must undoubtedly be washed. This is not possible with normal vibration engines since they may suffer from water damage and mold. Nonetheless utilizing an encapsulated motor which has been appropriately sealed (as talked about above in OverMolding & Sealing area) allows the clothing and haptic vibrations become perspiration and waterproof.

This opens up many different feasible programs which will formerly happen not practical:

- Performance indicators for athletes

- Wearable vibrating sleeves to stimulate blood flow for physical fitness, wellness, or health functions

- Haptic comments allowed garments, enabling the operator to keep two automatically, helpful for security purposes, artists (e.g. drummers), etc

- Washable vibrating collars or clothing for pets

Encapsulated Vibration Motors Overview

Non-covered eccentric rotating mass vibration motors require room for the eccentric size to go freely and generate vibration. If there is an opportunity that offset size are obstructed after that encapsulated motors are a great option.